Making wine at home can be a wonderful experience and a source of great pride. However, most vintners don’t talk about the less glamorous side of winemaking:

How to clean and sterilize wine making equipment.

It’s not fun, but you will regret taking any shortcuts.

Unsterilized wine making equipment is the most common source of spoiled wine. If you’ve ever tasted wine that was “off” or just didn’t taste right, then the culprit was likely some leftover bacteria in the equipment.

It’s important to thoroughly clean and sterilize (not just sanitize) your wine making equipment not only to avoid spoiled batches of wine, but also to avoid some other hazards of unclean equipment such as:

- Pitted stainless steel equipment

- Ruined oak barrels

- Shattered Carboys

- Even trips to the hospital

So what’s the best way to clean and sterilize your wine making equipment? This article will show you.

It’s a Two-Step Process

Cleaning and sterilizing wine making equipment is a two-step process. First you must clean any debris or gunk from your equipment otherwise the sterilizing agent may not be effective. Sanitizers and sterilizers do not contain surfactants or other cleaning agents so you must clean the equipment first. Don’t skip this step!

Second you must sterilize the wine making equipment to kill off any organisms that may spoil your wine. This step is even more important than the first. It cannot be skipped or rushed. There are several products and methods to sterilize wine making equipment as you will see below.

What Wine Making Equipment to Clean and Sterilize

When you learn how to clean and sterilize wine making equipment you will realize that ALL equipment must be cleaned and sterilized. Seriously, any equipment that will touch the juice, must, or wine during the entire wine making process must be cleaned and sterilized before and after every use. No exceptions.

This includes:

- Tubing

- Wine bottles

- Carboys

- Jugs

- Primary Fermenters

- Secondary Fermenters

- Barrels

- Bungs

- Air Locks

- Racking Cane

- Funnels

- Pumps

- Wine Thief

- Hydrometer

- Corks

- Stirrers and degassers

- Brushes

- Etc.

What Cleaning and Sterilizing Products Come in a Wine Kit?

Most All-in-One wine making kits and even fruit wine making kits usually include a cleaner and sterilizer. They should be all you need but you may want to upgrade to a better cleaner or sterilizer if the kit you plan to buy doesn’t have the one you want.

This popular fruit wine making kit from Master Vintner includes OneStep (a popular no-rinse cleanser) and Sodium Metabisulfite (for sterilizing).

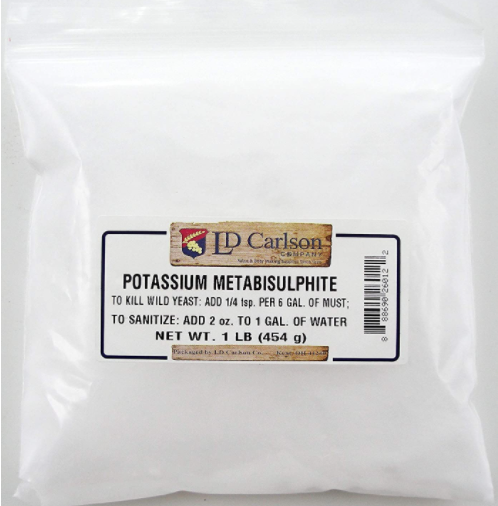

Some winemakers insist on avoiding adding any sodium to your wine while others argue the trace amounts of sodium will make no difference. If you want to avoid using sodium and your preferred wine making kit includes it, then you should separately purchase Potassium Metabisulfite as your sterilizing agent.

However, many wine making kits may only offer campden tablets (Potassium Metabisulfite in tablet form) for sterilization which are harder to measure. If that’s the case, you may want to purchase some Potassium Metabisulfite in powder form.

Also, you may want some additional accessories such as brushes and drying racks to make the process much easier. See below for tips on other equipment you may want to clean and sterilize your wine making equipment.

How to Clean Wine Making Equipment

The first step in cleaning your winemaking equipment is to remove any gunk and debris so the cleaning solution can do its job. Rigorous swishing motion with warm water will help to get the stuck grime off in hard to reach places.

Pro Tip: Use a wet rag inside carboys to help clean the inside surface. Turn it over and over until the rag has brushed the entire inside surface area. This article and video from Midwest Supplies explains this carboy cleaning technique well.

For tougher grime you should invest in a drill attachment like this one that will give you more muscle when cleaning your carboy.

Pro Tip: Sometimes it may be better to throw away any cheap but stubbornly stained equipment such as tubing. It’s much better to start with a clean, inexpensive piece of equipment than ruin a perfectly good batch of cabernet.

Avoid scrubbing plastics with any brush or material that will scratch it leaving refuge for microbes which will spoil your next batch. Use only oxygen-based cleaners like Hydrogen Peroxide or Percarbonates, which are a combination of sodium carbonate and hydrogen peroxide. Never use a chlorine-based cleaner because they can leave mustiness in your wine making it taste “corked”.

Oxygen Based Cleaners

P.B.W. (Powder Brewery Wash) – PBW is a percarbonate that has one of the highest strengths of the Percarbonates listed. It was originally created for Coors Brewing. It is effective in dissolving stains in hard to reach places like hoses, airlocks, fermenters, etc. A good 30-minute soak should work but for stubborn stains you may want to soak longer.

One Step No-Rinse Cleaner (AKA Aseptox) – One Step is a very popular, no-rinse cleaner. It creates hydrogen peroxide when combined with water. After doing its thing, it degrades into oxygen and water and trace minerals found in everyday drinking water. You just dissolve one tablespoon into one gallon of warm water and wash/soak all of your winemaking equipment for a few minutes.

B-Brite – B-Brite is a popular percarbonate-based cleaner that is great at removing wine labels and stubborn deposits. However, it does require a rinse to remove residues.

Proper Cleaning Technique for Wine Bottles

Washing wine bottles the right way is crucial to making good wine. Unless you invest in a bottle washer attachment for your sink, there really is only one good way to get clean wine bottles.

Buy a good brush set with varying sizes like this one on Amazon. You need a brush long and sturdy enough to scrub the sediment that settles at the bottom of wine bottles.

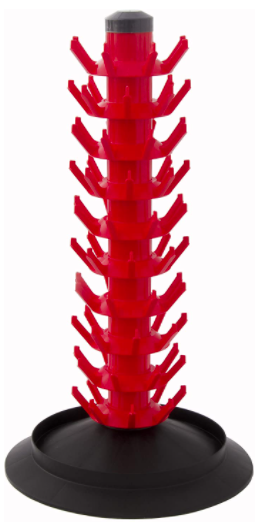

Also, do yourself a huge favor and get a drying tree rack. It will make air drying your bottles easy and help keep them sanitized.

You should never use dish soap when cleaning your wine bottles. Soap can leave residue and alter the taste of your wine.

Proper Cleaning Technique for Brushes and Scrubbing Utensils

You should also clean all your brushes and scrubbing utensils. The best way to do this is to spray them thoroughly or soak them in a sulfite solution. Do this before use and again immediately after use. Air-dry them thoroughly by placing them on a drying rack. It will greatly reduce any bacteria present on your cleaning utensils.

Proper Cleaning Technique for Racking Tubing

Cleaning racking tubing can be difficult. The best method is to let them soak in an oxygen based solution like B-Brite and water the night before you use them. This is an effective way to clean them inside and out. Fill the bottom of your primary fermenter with enough solution to cover the tubing, soak overnight, and rinse them off in the morning.

Can I Use a Dishwasher to Clean Winemaking Equipment?

[Image of steam cycle dishwasher]

You may be tempted to just stick all your wine making equipment in your dishwasher. I don’t recommend it. It won’t do a thorough job of cleaning the hard to reach places and the soap residue could spoil your wine taste.

You may want to run a rinse cycle and high heat to help sanitize some equipment but that’s about all you should use a dishwasher for when it comes to homemade wine making.

How to Sterilize Wine Making Equipment

The second step is to sterilize your wine making equipment. Again, all equipment must be sterilized. Don’t just skip to this step thinking your wine equipment will be cleaned AND sterilized with sterilizing agents. It won’t. Sterilizing products do not have cleaning agents so you can’t skip the cleaning step.

Sanitizing Products

Sodium Metabisulfite – Sodium metabisulfite is a common wine additive used to preserve wine and prevent oxidation. However, in a stronger doses it can also be used to sterilize wine making equipment. It’s relatively inexpensive to make. TO SANITIZE: Add 2-3 tablespoons into one gallon of water (50 grams in four liters). This makes a concentration just over 1%, which will sanitize any surface it’s in contact with within ten minutes. Do not use it on metals as it may corrode them.

Potassium Metabisulfite – Potassium metabisulfite is more commonly used as an additive to sanitize wine musts. However, higher doses of potassium metabisulfite are very effective in sanitizing equipment without adverse effects. TO SANITIZE: Make a solution of 2 oz of potassium metabisulfite added to 1 gallon (4 liters) of water, and then rinse your equipment in this solution for about 5 minutes to sanitize, and let drip dry.

Campden Tablets – Campden tablets are usually the same ingredient as Potassium Metabisulfite pressed into tablets but can be made from sodium metabisulfite as well. Many wine making kits will come with campden tablets for wine must sanitizing but also advise you to use them to sanitize your wine equipment too. Campden tablets are not ideal for sterilizing wine making equipment because they need to be crushed so it is hard to get the exact amount needed for mixing.

Iodophor – Iodophor contains iodine and is widely used in the brewing industry as a sterilizer. It’s less expensive than other sterilizing products. Mix it with water according to instructions. Spray or soak wine making equipment for about 2 minutes and allow it to air dry.

Acid Sanitizers – Acid sanitizers usually contain phosphoric acid that foams and can penetrate cracks to clean tough to reach spaces. It doesn’t need to be rinsed when mixed in the proper dose. Many homemade wine enthusiasts find an acid sanitizer like StarSan easier to work with. It’s also very cost effective because the solution can be reused if it is properly sealed. The downside is they are corrosive to soft metals so read the warnings before using.

Can I Use Heat to Sterilize Wine Making Equipment?

Yes. In fact, this is how many commercial breweries and vineyards sterilize some equipment. That’s because high heat will kill off most organisms.

Some home vintners will use their oven or dishwasher’s steam cycle to sterilize some of their wine making equipment. However, dishwashers can only reach about 150º to 170º F. That temperature will only sanitize, not sterilize your equipment. Sterilization requires temperatures above 200º F.

If you want to use your dishwasher to sanitize your wine making equipment you should run it without any detergent. Also, should you obviously avoid high heat with tubing or any other plastic items.

How to Make a Sanitizing Spray Solution

Sometimes the best way to clean some of your wine making equipment is to spray it with a sanitizing solution. Here’s how to make your own spray sanitizing solution at home:

- Use a chemical resistant spray bottle. Preferably one with measurements so you can accurately mix your solution and an adjustable spray nozzle.

- Mix the appropriate amount of StarSan for your desired amount of spray sanitizer. FIve Star Chemicals, the maker of Star San, suggests 1 oz of Star San for every 5 gallons of water. That’s ⅕ oz per gallon. For a 32 oz spray bottle, you will need 1/20 oz or about 1.5 milliliters of Star San per 32oz of water. You can use a children’s medicine dosing cup or a dropper to accurately mix it.

- Spray 6-8 inches from surface

- Allow for contact time of at least 1-2 minutes.

- Drain, but do not rinse.

It’s also good for sanitizing other equipment that is compatible with a diluted acid solution. Avoid aluminum and pet dishes.

More Tips for Sanitizing Wine Making Equipment

Here are a few other tips to keep in mind when sanitizing wine making equipment.

- Don’t soak any plastic things in a sulfite solution for too long. It can make them brittle and subject to cracking. It will also ruin rubber bungs.

- Many sanitizing solutions do not require rinsing but you should always allow materials to drip dry. Invest in a bottle tree.

- Repeat the clean and rinse step if debris remains or you smell residual cleaning agents

- Keep dedicated cleaning supplies such as brushes and all scrubbing utensils for cleaning wine making equipment

- Never clean your wine making equipment with a chlorine-based cleaner or your risk losing your wine batch

Conclusion

Cleaning and sterilizing your wine making equipment is a tedious but necessary step in wine making and home brewing of any type. It involves two equally important steps. First, you must thoroughly clean all wine making equipment so that no debris remains. Second, you must sanitize the equipment to ensure no microbes spoil your win batch.

If you follow the above guide and do not cut any corners you can be sure your next batch of wine will not be spoiled due to unclean and unsanitized equipment. The rest is up to you! 🙂